Incremental forming

PETG molds for plaster tiles.

Team : Naomi Grigoryan , Miranda Bibb Instructor: Christopher Humphrey Year: 2022

Location: Ann Arbor MI, USA Phase: Built Prototype

Introduction

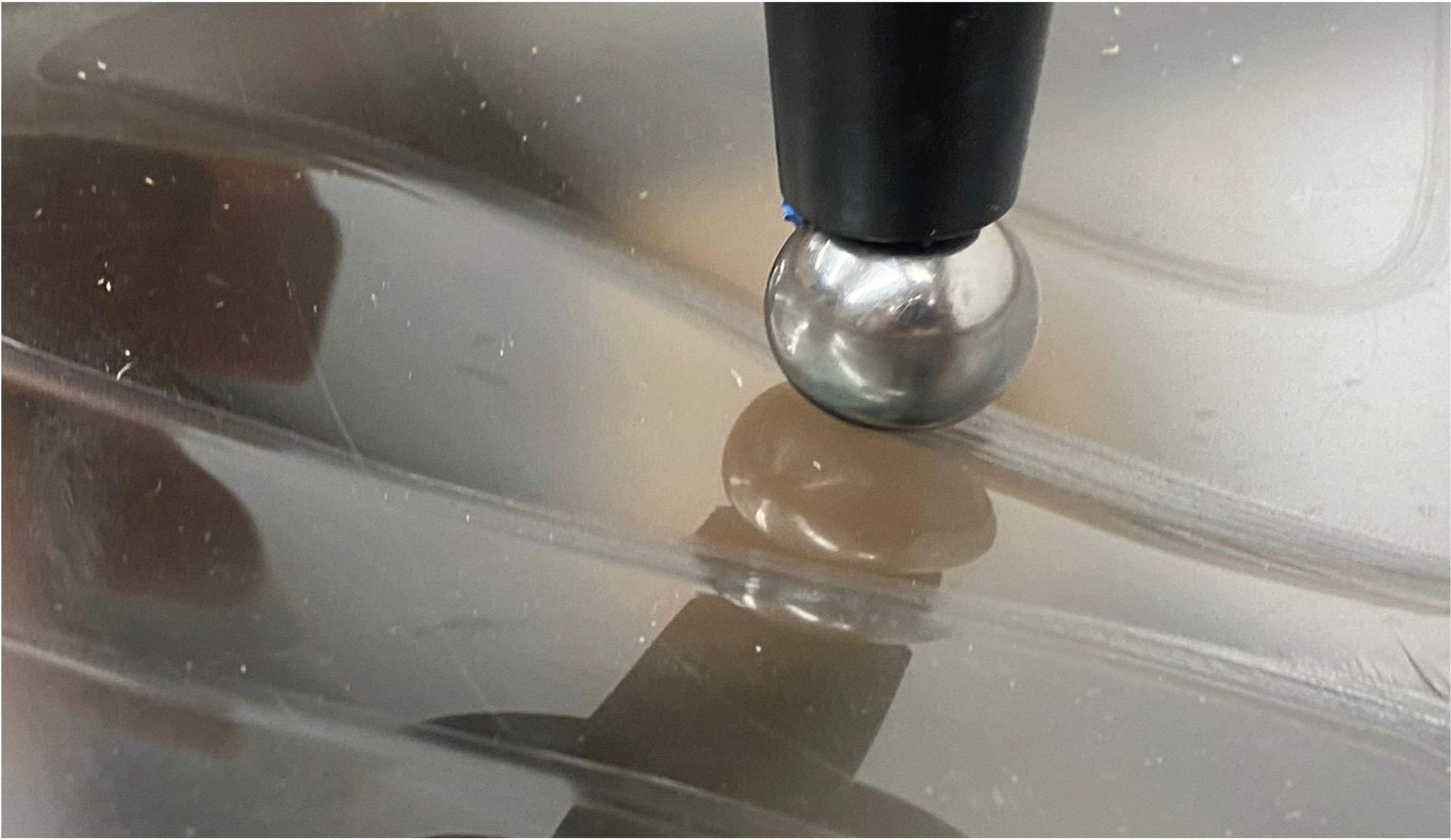

In this project, a workflow was established for creating reusable models of plaster tiles through robotic incremental forming. The design process began by creating a parametric facade, which was then discretized into multi-tiles. Subsequently, a tool path for the KUKA Kr6 robot was developed to form a PETG sheet. The logic used in the tool path aimed to minimize material deflection and achieve consistency by employing different-sized metal balls as a forming head. The PETG sheet, once formed, served as a material for a mold for plaster tiles. In this phase, plaster fiber and fiber optics were integrated as a lighting unit for the tiles. The project involved a systematic approach, from initial design to robotic forming, and finally, the use of the formed sheet as a mold for innovative plaster tiles with integrated lighting components.

Design Process

The fabrication setup showcases the utilization of a KUKA Kr6 robotic arm in conjunction with a PETG sheet. The robotic arm is strategically positioned to execute precise tool paths, forming the PETG sheet with a logic-driven approach to minimize material deflection. This image captures a pivotal moment in the workflow, highlighting the advanced technology and methodology employed in the production of reusable models for plaster tiles. Slicing was done in Grasshopper, enabling parametric segmentation. Tool path development utilized KUKA PRC for precise control of the robotic arm, ensuring accurate execution. This integrated approach underscores the project's efficiency in automated fabrication.

Incremental forming process

The images reveal the implementation of sorting logic for tool path optimization, effectively minimizing material deflection. Varied ball sizes contribute to enhanced surface accuracy. These visuals showcase the project's commitment to precise fabrication techniques for optimal results.

Casted Tiles

During casting, fiber optics were integrated for both aesthetic appeal and functional lighting elements. The deliberate addition of fiber optics seamlessly embedded a dynamic lighting solution within the structure. To enhance luminosity, a fluorescent material was carefully introduced to the casting mix. This strategic combination not only brightened the tiles but also created a captivating interplay of light and form. The outcome is a collection of illuminated tiles serving a practical lighting purpose and showcasing the fusion of innovative materials in architectural design.