MOD(ular) PODS

Team: Stuti Bindlish, Raha Kamravafar, Instructor: Dr. Mania Aghaei Meibodi Year: 2023

Location: Ann Arbor, MI, USA Phase:Built Prototype

Introduction

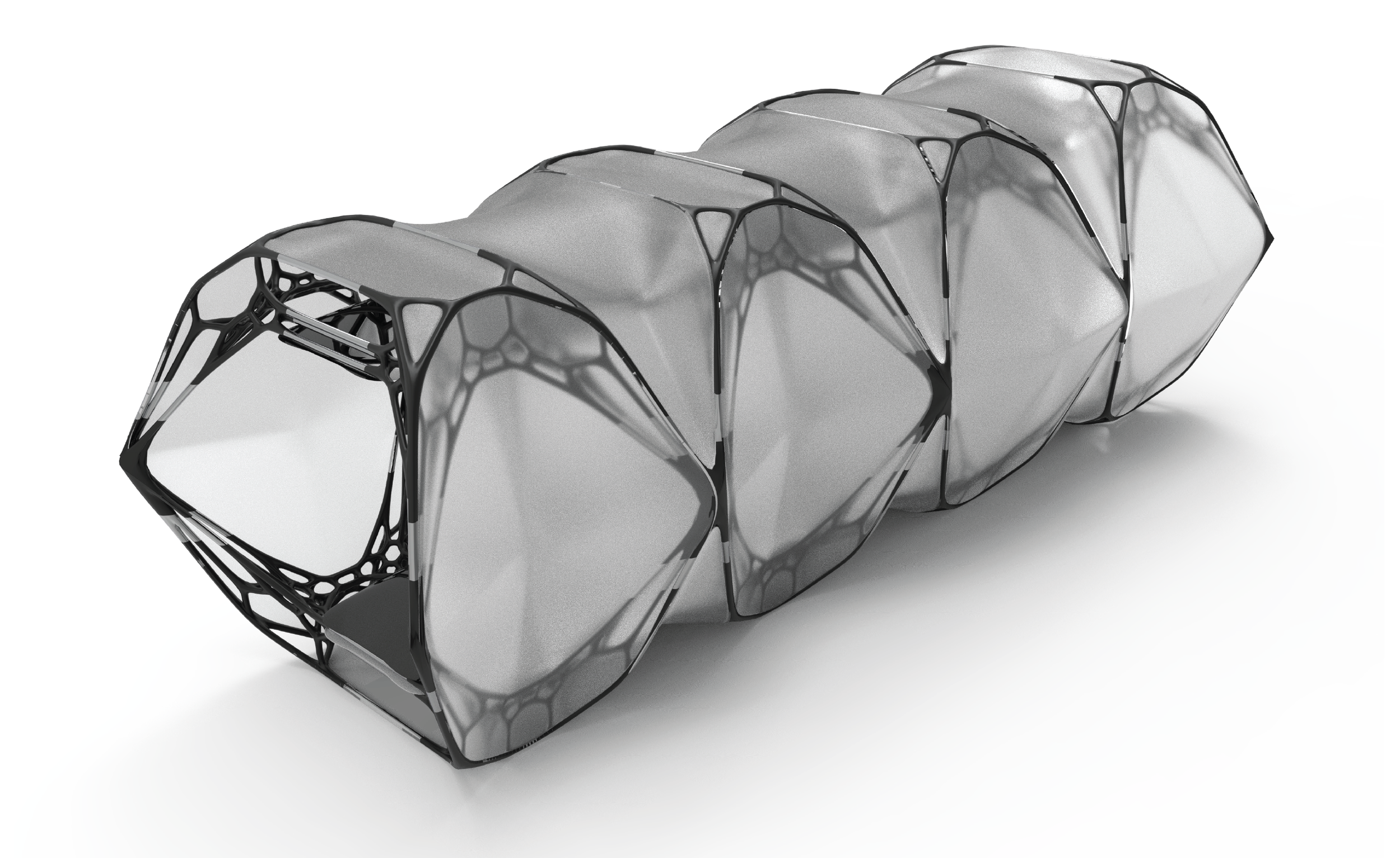

The Mod(ular)Pods project addresses the growing demand for affordable and accessible housing in the face of increasing urbanization. This ongoing research initiative focuses on innovative construction techniques to tackle the housing crisis. Utilizing space frame structures for their lightweight, efficient, flexible, durable, cost-effective, and aesthetically appealing attributes, the project employs graphic statics as a form-finding method. This approach produces optimized complex branching geometries that excel both in material efficiency and structural performance.

The Mod(ular)Pods project addresses the growing demand for affordable and accessible housing in the face of increasing urbanization. This ongoing research initiative focuses on innovative construction techniques to tackle the housing crisis. Utilizing space frame structures for their lightweight, efficient, flexible, durable, cost-effective, and aesthetically appealing attributes, the project employs graphic statics as a form-finding method. This approach produces optimized complex branching geometries that excel both in material efficiency and structural performance.

Form finding

Initial Form Finding Iterations Initial Brep Finalised Form Initial Brep Sub division Form Diagram Sectional Module Subdivision Dual Form Diagram Geometry - Single Assembled Unit In the initial design development of the space frame, the form-finding technique of graphic statics was instrumental. This approach facilitated the creation of a network of lines, offering crucial insights into the critical members essential for the overall structure and those experiencing tension or compression forces. The primary emphasis during this phase was on simultaneously developing an optimized system and designing the form. This proactive approach allowed for enhanced control over the structure's geometry, employing subdivision techniques on the same polyhedral. The subdivision was strategically executed to prevent buckling in the longer members, ensuring structural integrity.

Form finding

Following the creation of the initial module, the team proceeded to segment the form into intricate joints suitable for 3D printing, alongside standardized rods for easy sourcing. This segmentation enhanced flexibility and efficiency during the assembly process. The current design proposal comprises four modules, each incorporating two significant joints. One functions as the edge joint, while the other facilitates seamless assembly with the subsequent module. This modular approach ensures a streamlined and accessible assembly process for the overall structure.